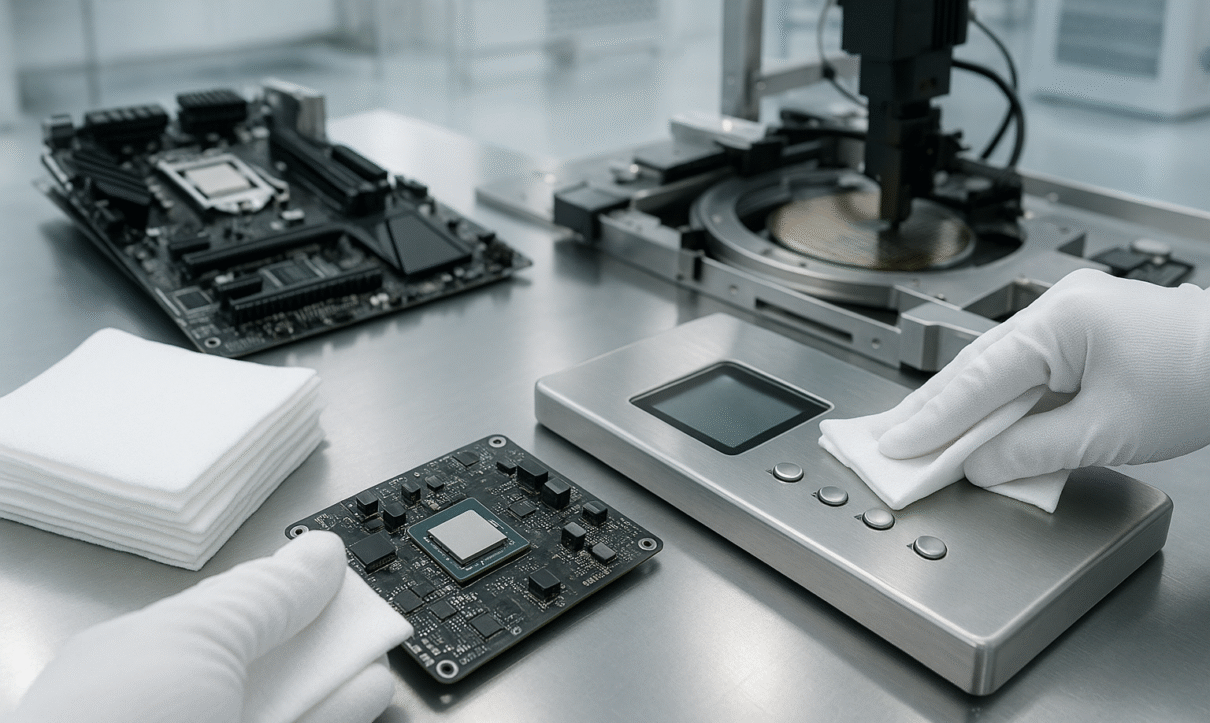

Our nonwoven products ensure contamination control and precision cleaning for electronics manufacturing. Designed for cleanroom environments, they meet strict classifications and provide reliable performance for sensitive component production and maintenance.

Semiconductor Manufacturing

Wafer Processing Areas Semiconductor fabrication requires Class 10 cleanroom conditions where even single particles can destroy products. Our cleanroom-certified nonwoven wipes generate minimal particles while providing effective cleaning of critical surfaces and equipment.

Assembly & Packaging Operations Electronic component assembly demands static-safe cleaning materials that prevent electrostatic discharge damage while maintaining contamination control throughout the manufacturing process.

Quality Control & Testing Precision measurement and testing equipment requires cleaning materials that won’t introduce variables or contaminants that could affect measurement accuracy or product reliability.

Electronic Component Manufacturing

PCB Assembly & Production Printed circuit board manufacturing requires cleaning materials compatible with flux removers and other electronic chemicals while providing lint-free performance that prevents short circuits and component damage.

Component Inspection & Handling Electronic components require gentle cleaning that removes manufacturing residues and contaminants without damaging delicate leads, connections, or surface-mount components.

Rework & Repair Operations Electronic repair work demands precision cleaning materials that enable detailed work while preventing contamination that could affect repair quality and reliability.

Cleanroom Facility Maintenance

Environmental Monitoring Cleanroom certification requires ongoing monitoring and maintenance of contamination levels. Our validated nonwoven products support contamination control programs with documented particle generation data.

Equipment & Instrumentation Cleaning Cleanroom equipment requires specialized cleaning materials that maintain performance while meeting strict contamination control requirements for different cleanroom classifications.

Facility Infrastructure Maintenance Cleanroom facilities require cleaning materials that support environmental control systems while maintaining the contamination control standards required for ongoing operations.

Quality We Ensure

Cleanroom and electronics applications require the highest quality standards with comprehensive testing and validation. Our products undergo particle generation testing, chemical compatibility evaluation, and cleanroom classification verification.

Experienced Cleanroom Support

Cleanroom and electronics cleaning requires specialized knowledge of contamination control principles, industry standards, and application techniques. Our technical experts provide consultation and validation support for critical applications.

Electronics Industry Benefits:

- Cleanroom certified for Class 10 to Class 100,000 environments

- ESD-safe materials prevent electrostatic discharge damage

- Ultra-low particle generation maintains contamination control

- Chemical compatibility with electronic cleaning solvents and chemicals

- Validated performance data supports contamination control programs

Electronics Applications:

- Semiconductor fabrication facilities

- Electronic component manufacturing

- Printed circuit board assembly operations

- Pharmaceutical and biotechnology cleanrooms

- Aerospace and defense electronics manufacturing

- Medical device production facilities

- Optical component manufacturing

- Research and development laboratories

Service Information

- Cleanroom Certification: Complete validation data and cleanroom classification support

- Technical Validation: Expert consultation on contamination control requirements

- Custom Solutions: Specialized nonwoven products for unique cleanroom applications

- Quality Documentation: Comprehensive quality records and batch certification data

Products